There is also a noun form available for the word "welding."

If you use welding techniques such as gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), and metal inert gas (MIG) welding, you will be able to produce a connection between two or more sections that is both stable and long-lasting. This is the case even if the number of sections involved is greater than one. The joining of two or more pieces of material together can be accomplished through the use of these techniques by means of an electric arc.

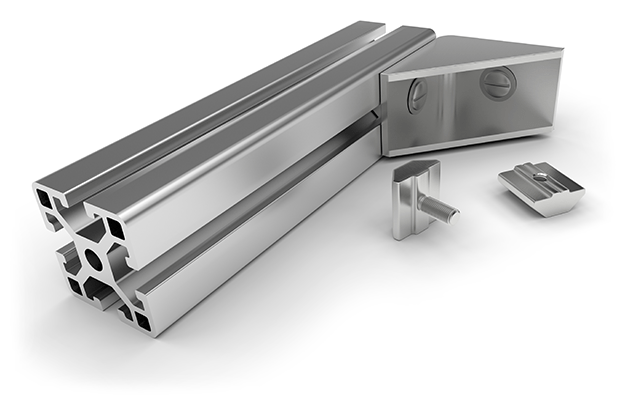

As a result of their adaptability and flexibility, the uses for fasteners can cover a very wide variety of different possibilities. When protecting fasteners from corrosion, it is common practice to plate the surface of the fasteners with a material made of zinc or cadmium. This prevents corrosion from occurring on the fasteners.

Epoxy structural adhesives have the capability of forming bonds that are not only able to endure vibration for an extended period of time, but also have the ability to endure significant amounts of time. When compared to various other kinds of structural adhesives, this is a significant advantage. Due to the fact that they possess these qualities, they are an excellent choice for applications that require Aluminum Profile that has complex geometries. As a result of this, they are an excellent choice for applications that call for these kinds of profiles.

This holds true in particular for gauges that are of a thinner thickness. In order to join panels together, rivets are typically used.

Combination rivets are required whenever two or more materials of varying thicknesses are to be joined together. This includes any situation in which two or more materials are to be joined. This includes circumstances in which the individual materials have varying degrees of thickness.

A relatively recent method of joining, adhesive bonding makes use of high-performance structural liquid adhesives like epoxy resins or acrylic acids. This method of joining is considered to be one of the more modern methods of joining. This technique of affixing parts together is one of the more recent developments in the sector of the industry. In the event that the procedure is carried out as planned, this is one of the outcomes that might occur. This technique is straightforward to implement, naturally seamless, offers a high resistance to impact, and imposes only a few restrictions on the size and shape of the Aluminum Profile that can be used. Because of these advantages, selecting this alternative is a smart choice.

People are able to comprehend the arguments that are being made on both sides of the debate as a result of the presentation, which is visually very impressive.

The friction plug welding technique utilizes a rotating pin or sleeve with a shouldered tip that generates heat through friction in order to plasticize and displace the aluminum as it is inserted. This allows the aluminum to be welded without cracking or breaking. Because of this, welding aluminum doesn't result in any cracking or breaking of the material. Due to the nature of the process, welding aluminum does not result in any cracking or breaking of the material. This is true even though the material is brittle. This self-piercing process can be used with materials that are not analogous to one another, and it leaves a neat weld on the frontside of the joint that it creates. Additionally, the process does not require the use of any additional tools or equipment. In addition, the process does not call for the utilization of any additional instruments or apparatus of any kind. As a consequence of this, it is suitable for use in a wide variety of applications, including those involving automotive body panels.

There are also cutting-edge methods that can be used, such as flow drilling, which creates a connection that is form-fitting while simultaneously drilling and tapping screws in a single step. Flow drilling is one example of a method that can be used. Flow drilling is just one example of a method that may be utilized. Other methods include. Flow drilling is just one of the many methods that are at your disposal right now; in addition to this, you have access to a wide variety of other possibilities. In order to arrive at a conclusion regarding the approach that will be taken to complete the project, the specific requirements of the task will serve as the primary factor that needs to be taken into consideration.